56182 Class 104 Driving Trailer Composite Lavatory

Home Railway |

Location History |

Churnet Valley RailwayJun 00-Feb 15 |

|

Current Location |

|

North Norfolk Railway Feb 15-Present |

|

Current Status |

Operational |

||

Current Livery |

BR Green (Speed Whiskers) |

|

|

TRA Designation |

|||

Partner Vehicle(s) |

|

|

|

Owner |

Chris Moxon & Paul Moxon |

|

|

Website |

|||

Record Last Updated |

23 November 2024 |

||

Preservation Modifications In turn many minor, but often hidden, modifications were made during the restoration to improve maintenence or usability in the future. These include: |

|||

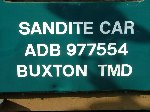

Preservation Information However the extended life which the departmental role gave the vehicle allowed it to eventually be preserved, joining the other 12 Class 104 vehicles which were saved in 1992. It was prepared in 1998 for a move to Barrow Hill Roundhouse, a proposal which later fell through. In 2000 however, the vehicle was finally moved to the Churnet Valley Railway, having to be craned out from Buxton TMD onto the road transporter as the rail connection to the depot had been removed! 56182 had to integrate with a 104 restoration plan formulated in the mid 1990’s in which the vehicle played no part. It therefore “joined the queue”, taking its place in storage at Oakamoor Sand Sidings, while the restorations of 50455 & 50517 were completed. As 56182 was in better condition than the DMCL for the Churnet Valley’s second 104 set, 50437 & 50494, 56182 was earmarked for restoration alongside 50437 to provide a second 2-car set, which would have been fitting as the pair had operated together for a period during BR days. However after completion of 50455/50517’s restoration, the Churnet Valley requested a quick capacity boost as the 2-car set was not providing enough seats for busier events. This led to TCL 59137 (a vehicle in much poorer condition than the others) jumping the restoration queue due to its operational appeal in creating a 3-car set. 56182 therefore remained in storage. In November 2004, 56182 was sheeted over to offer some protection from the Staffordshire winters. In July 2008, the vehicle was dragged out of storage and unsheeted, and was treated to a 2 month “fast-track” external restoration which included a brush up and a coat of BR Blue. The mechanics of the vehicle were also serviced to a standard where it was capable of being operated as a hauled Sandite coach again with a diesel loco. In September, the vehicle was resplendent alongside 37075, and recreated the Buxton Sandite trains at the Scenic Railcar Weekend. After the event, 56182 returned to storage. In October 2012, 56182 was attacked by metal theives whilst in storage. Many "removable" items from the exterior were forcably detached and stolen. This triggered some essential work to resecure the vehicle, with remaining parts which were relatively easy to remove on the outside being taken from the vehicle and transferred to a more secure location. The vehicle was then resheeted with replacement tarpaulins and returned to store. During 2013 the vehicle suffered further attacks with all the cabling underneath the vehicle being stolen and several windows were also broken when thieves forced entry. January 2014 was an important milestone in 56182's history, with the announcement that its full restoration to original condition was to commence. That same month saw the interior woodwork from the sides of the passenger saloons stripped out for restoration off site in Norfolk. Subsequent months saw these components stripped of old varnish, sanded, revarnished and then stored awaiting refitting later in the restoration. The first of these were completed in July. July also saw electrical and cosmetic restoration of the cab components start, this work continuing until the end of the year. In February 2015, agreement was reached to progress the restoration of 56182 at the North Norfolk Railway and operate it there once completed. The vehicle was duly relocated from the Churnet Valley that month. Due to a lack of siding space at the North Norfolk Railway's main workshops at Weybourne, 56182 was immediately put inside Bridge Road carriage shed at Holt and work on the interior components continued. Most of the fibreglass panels which form the interior of the cab were restored during this period, along with many air and electrical components removed from the cab desk. The four wooden interior sliding doors and many toilet fittings also received attention. During November, capacity in the yard at Weybourne became available and 56182 was accommodated next to the Carriage & Wagon workshops where work on the vehicle itself could begin. The early part of 2016 saw the refurbishment of the six exterior doors undertaken, which were then stored in component form ready for reassembly. The spring saw a break from 56182 itself whilst a restoration tent was built around the front third of the vehicle. This allowed the commencement of the bodywork repairs and the First Class saloon was repaired during the early summer. The autumn saw bodywork concentrate on the cab front, which had most of its framework renewed during this period. The panelwork was unable to be finished however as issues were encountered obtaining replacement laser cut panels. Significant corrosion was found under the cab floor so this all had to be ripped out and replaced during the winter. Into 2017, the first task was serious repairs/rebuilding of damaged roof domes and cab ceilings, both of which were made from fibreglass. These alone took until May to complete! During the year, the seating was repaired and reupholstered, which was done prematurely as advantageous terms of payment were available at that particular time with the upholsterers. The upholstered seating was stored to await its time to shine! By the autumn, the roof above the first class area of the vehicle had been stripped back to bare metal, original roof vents reinstated and then repainted. The gutters were also cleaned out and repainted. During the winter months, all of the wooden retaining bars that hold the glass into the first class saloon were stripped, repaired and revarnished. Also restored were the aluminium window frames from the same saloon and the sliding lights. The two ceiling panels from the first class saloon were repanelled, framework repaired and then repainted ready to refit. In 2018, the first task was serious repairs of the cab-to-passenger-saloon bulkheads which had suffered from water ingress. This involved veneer splicing amongst other skills followed by heavy sanding and the more usual repairs and revarnishing. Other components restored in the spring included the dynamo, horns and the six exterior bodyside door skins which were remounted on their frames and painted. The remainder of the year was spent stripping down the vehicle's frames and equipment between the two bogies and repainting. 2019 saw work start reassembling the first class saloon interior. The rebuilt bulkheads were returned into position, the section glazed and the interior refit progressed. Insulation, ceilings, new wall panelling and all associated woodwork and fittings were returned into place. During the summer more underframe equipment was returned to the vehicle post restoration including the battery boxes, vacuum tanks, and fuel tank. The final part of the year saw a big push getting the exterior of the cab end and first class area complete. This included sanding, filling and repainting work, the replacement of all metalwork on the cab front skin, reinstallation of the cab doors, glazing of the cab front and refitting of the fibreglass outer roof dome. The target was to get the front 1/3rd of the vehicle watertight and moved out of the restoration tent before the year was out, which was achieved with just days to spare! 2020 was to prove an extremely strange year, in which 56182 profited massively. An eight month period of furlough for the restoration's team leader allowed full time restoration to progress for the first time, after the initial "lockdown" period of the Covid-19 pandemic had passed. This allowed an estimated two years worth of restoration to be completed in just a few months. The three main areas of attention were the cab, middle passenger saloon and underframe. The cab was almost completely fitted out to completion, with the fibreglass ceiling and wall panelling being restored and fitted, following which reconstruction of the desk allowed all the drivers instruments and controls to be fitted out. The wiring up of the cab kick-started the long-awaited rewire of the vehicle. This was originally to be done in many stages, but the opportunity was taken to continue and progress the heater, power supply, underframe and multiple working wiring in one go. By December the entire vehicle had been completed, at long last reversing the devastating effects of the copper thieving ten years earlier. Meanwhile the middle passenger saloon received all of its replacement metalwork, both skin and framework, where required. Missing rear bulkheads were returned to place and all the bulkheads in that area restored. The ceilings were also dropped, renewed, refitted and populated with the required fittings (lights, grills etc). The original plywood floor was removed and completely replaced after being found to be more rotten than first thought. The year of advanced progress was brought nicely to a close with a period inside the railway's main shed, where 56182 was lifted for the first time in preservation allowing the bogies to be rolled out to give access for the areas of underframe above them to be needle gunned to bare metal and fully repainted (the underframe between the bogies had been so treated back in 2018). This was achieved at the same time as the rewire allowing the trunking and various pipes to be painted, colour coded. The announcement of a second national lockdown in November further extended M56182's stay inside the shed, as the railway had little use for that particular spot with so many staff and volunteers not present on site. The increased progress rate (and shed space) continued into 2021. Progress was so swift that the previous mantra of undertaking 56182's restoration in three distinct phases was collapsed and instead the renewed aim was to bring the whole vehicle to the same level as the front end. The previous exterior bodywork on the middle saloon was repeated for the rear section and the remaining 2/3rds was grit-blasted (in July), sanded, filled and repainted into gloss green to match the front third. The two bogies were fully stripped down, overhauled and repainted which included tyre turning and replacement coil springs on the front bogie. Internally, the rear saloon (previously untouched) was completely stripped out allowing for the middle and rear saloons to receive replacement flooring. The inside of the rear saloon was cleaned up, repainted and insulated. By the autumn the space in the shed was coming to an end so window glass and the remaining doors were swiftly refitted allowing the vehicle to return outside in the October. Early 2022 saw many of the last removed interior components restored inside the shed during the colder months. A salvaged corridor connection from a Class 101 was also stripped down, rebushed and repainted ready for reuse. Work continued on the interior with the second class veneered wall panelling and window surrounds being fitted along with the rear saloon ceilings and light fittings. Mechanical work continued with a new set of batteries being fitted and the air and vacuum system completed. In March 2022 a milestone was reached when the restoration had advanced to the stage where 56182 undertook its first test runs paired with Class 101 51188, the intended future partner for 56182. The rest of the year saw the interior reconstruction of the toilet brought to completion, which became the very first area of the interior ready to receive passengers. Other paneling work in the vestibules was completed with new veneered wooden door cards being fitted to the internal faces of the doors. 2023 would prove to be the final restoration year and the last push to completion. Externally the route indicator box and footboards were fitted anlong with new pipework for the fuel tank and heaters. A final coat of varnish was applied to the interior and then the lino flooring and carpets were laid. With flooring down, all of the components which fix to the floor which had been waiting in storage were all fitted into place including sliding doors, heater duct covers and of course the passenger seating. It was an exciting time with new components seemingly being fitted into place weekly. There was a myriad of smaller items, too many to list individually, fitted and tested to bring the vehicle to a state of mature assembly. By July the mechanics and interior were all but complete and 56182 was moved back into the railway's main sheds for the final time in order to apply the final coats of gloss varnish and of course lining and lettering. 56182 was launched into passenger service in September 2023 at a dedicated event at the NNR. A ceremony was conducted in the morning with speeches from the restoration team and Managing Director of the railway. A bottle of champagne was smashed over the buffers to launch the vehicle into service and a private charter down the line for supporters followed. At the other end, 56182 cut through a ribbon on arrival and various photographs were taken along with more drinks and of course cake! On return to the other end of the line further trips were made, the first runs with paying passengers in over 35 years. The remainder of the day saw the set haul a tail load for the first time in the railway's history and the final (daytime) trip was a simulated diesel hauled "drag". Evening trains then operated including a Fish & Chip special and several station stops where dusk and after-dark photographs were taken. Modest media covereage was enjoyed and 56182 had well and truly been celebrated back into service! 56182 then very quickly entered regular passenger service on the railway's ordinary DMU services, paired with partner Class 101 DMBS 51188. 56182 ran for total of 1, 513 miles in its first year. In July 2024, the final snagging left over from the restoration was cleared meaning for the first time in preservation ever, 56182 was 100% fault free with every item working exactly as it should, a very rare feat in preservation! By the end of the year, the vehicle had operated 7,517 miles over 159 running days, with 100% availability achieved. 56182 & 51188 regularly operate services on the NNR as one of two operational sets. |

|||

Future Plans In five to ten years time, it is the owning group's aspiration for 56182 to be paired with its long term intended partner Class 104 DMBS 50479, which will recreate the original (matching 104) 2-car formation as delivered in 1958. |

|||

Interior

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)